Overview

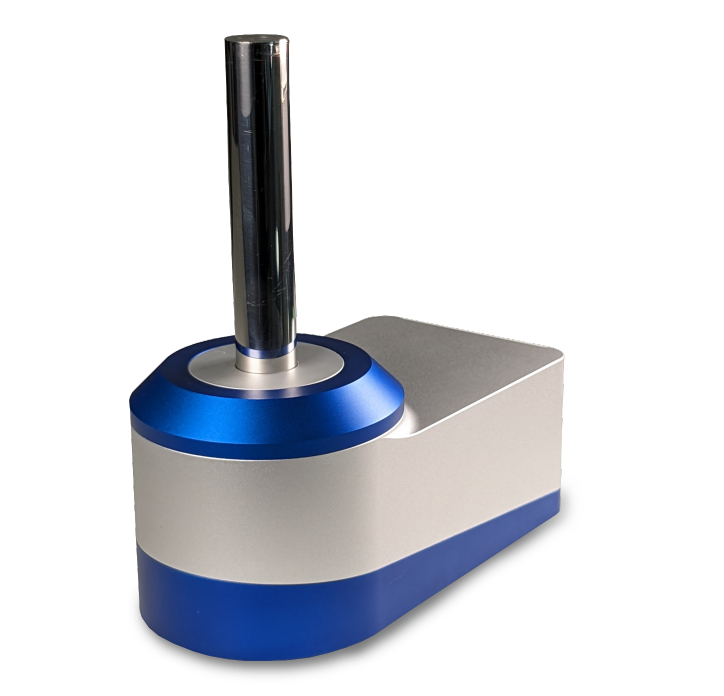

The SentroPAT Compact is a flexible, rugged NIR analyzer designed for non-destructive online monitoring of powders and granules in pharmaceutical and food manufacturing.

This system provides valuable process insight during process development and reliable process information when deployed in commercial operation. As our newest system, the SentroPAT compact benefits from technological and design innovations built on Sentronic's 30+ years of supporting in-line spectroscopic analysis.

- Compact, all-in-one NIR process analyzer

- Wide spectral range (1100-1900 nm)

- High stability due to internal intensity and wavelength standards

- Just one cable (power-over-Ethernet) connection required and

no fiberoptic cables need for installation - Easy-to-use and field-proven software control

Applications

While the capabilities of the SentroPAT system could benefit a wide range of industries, we have chosen to focus primarily on the pharmaceutical sector, particularly in the manufacturing of oral solid dosage forms.

As a result, nine of the world's top ten pharmaceutical companies have chosen Sentronic as a trusted partner for their process analytical needs.

The SentroPAT Compact as the latest adddition to the powerful SentroPAT family perfectly extends this capabilities and is compatbile to well known and established applications.

Technical Data

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

Frequently Asked Questions

Learn more about the SentroPat FO and its wide range of applications in pharmaceutical manufacturing. This section provides additional insights and detailed information to help you fully understand the potential and versatility of our cutting-edge sensor technology.

Expected that they last for the lifecycle of the instrument. Lamps no longer need to be changed periodically.

It is possible to do, albeit it results in some loss of signal-to-noise. It further introduces a risk of interference effects between the process sapphire and the probe window. This can be easily avoided by enuring a small gap between the two sapphires. It should further be ensured that the measurement of external standards, e.g. 99% spectralon standard, is done with the same setup and an additional sapphire as well.

We of course cannot promise any given application will successful or not without seeing spectra. However, several customers have implemented the sapphire process windows for containment with success and we're happy to evaluate solutions for certain requirements.

The SentroPAT FO has a wavelength range of 1100 - 2100 nm with a resolution of NMT 12 nm FWHM. The SentroPAT Compact has a wavelength range of 1100 - 1900 nm with a

resolution of NMT 10 nm FWHM. The wavelength and resolution are the most obvious differences between the two systems, in addition to some differences in signal-to-noise owing to the difference in cooling (SentroPAT FO) versus slight heating (SentroPAT Compact) used to maintain a consistent detector temperature.

Both the SentroPAT FO and SentroPAT Compact are capable instruments. However, for the most challenging applications or relevant absorbance bands are above 1900nm, it may be advisable to look at a SentroPAT FO due to the expanded wavelength range and lower noise. However, many if not most NIR PAT applications in pharmaceuticals can be well served by a SentroPAT Compact

Related Information