What if you could analyze materials faster, more reliably, and with minimal effort? At Sentronic, we’ve spent over 30 years perfecting our Near-Infrared (NIR) Process Analytical Technology (PAT) to make this a reality for your business. Our proprietary technologies and innovations provide you with fast, robust NIR PAT measurements that you can trust.

Today our solutions stand out for their:

- Robustness: Our systems deliver precise results even in challenging environments.

- Reliability: Count on consistent performance day after day, ensuring stable processes.

- Flexibility: Adaptable to different materials and measurement tasks.

- Consistency: Maintain high quality standards across all measurements.

- Service: Our experts support you from installation to everyday operations

We believe in open and transparent communication. Whether you're new to PAT or an experienced professional looking to optimize your processes, our goal is to share our knowledge and provide valuable insights to help you succeed.

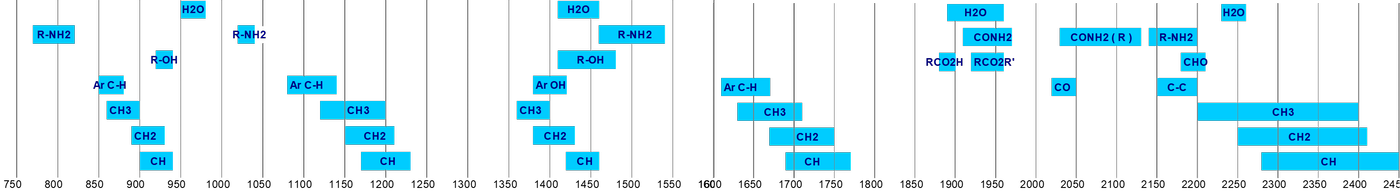

Near-Infrared (NIR) spectroscopy is a powerful and versatile technique for analyzing the chemical and physical properties of materials. It operates within the 780 nm to 2500 nm wavelength range, just beyond the visible red spectrum. NIR technology is widely used in spectroscopy, imaging, and telecommunications, offering a cost-effective, field-deployable, and non-destructive method for detecting changes in material composition. One of its key advantages is that it can be implemented in-line or at-line, providing real-time insights without requiring sample preparation.

The diagram above illustrates the characteristic absorption bands of various molecular groups in the NIR spectrum. These absorption features arise due to molecular vibrations, primarily overtone and combination bands, which allow for precise material identification and analysis. Key functional groups such as C-H, O-H, N-H, and C=O exhibit distinct absorption patterns at specific wavelengths, enabling the detection of crucial properties like moisture content, chemical composition, and molecular structure.

This makes NIR spectroscopy particularly valuable in pharmaceuticals, agricultural products, and environmental monitoring. It is also widely applied in material identification, moisture content analysis, and quality control. By leveraging advanced mathematical processing, NIR data can provide rapid, comprehensive, and actionable insights for process monitoring, making it one of the most efficient analytical technologies available.

Smart Probes Ensuring PAT Performance

Sentronic has developed a number of innovative, fit-for-purpose process probes for use with our NIR PAT systems. Whether it's for making measurements in the feed frame of a tablet press, in the slow-moving exchange section after a blender in a continuos manufacturing line, or in a challenging environment like a fluid-bed dryer, Sentronic has a wide variety of probe solutions.

In addition to the probes themselves, we have collaborated with a number of process interfacing and process simulator provides, such as Expo Process Analytics, to ensure our probes are compatible with process sampling tools like the Expo Spider Wheel or the GEA Consigma Light House assembly.

Internal Standards

Ensuring and verifying performance while keeping the system in-lineVibrational spectroscopy systems require regular calibration, referencing, or performance verification—Sentronic NIR systems are no exception. However, relying on external standards and removing the NIR system or probe for these tasks can be inconvenient.

To overcome this, Sentronic has developed internal standards for intensity and wavelength calibration. These minimize drift and allow users to verify system performance or suitability without removing the system from the process. This approach reduces reliance on external standards, enhances efficiency on the production floor, and ensures reliable NIR PAT results through in-line system suitability tests.

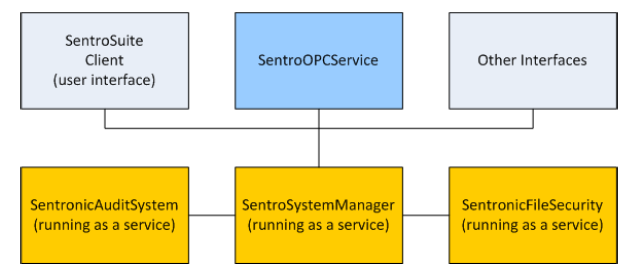

System Interfaces

Plug and Play Control with Major PAT Data Management and Process Control SystemsManufacturers increasingly want to have all process sensor data served to a single database directly, rather than pulling data into a database from each sensor. Software packages like Optimal SynTQ or Siemens SIPAT are commonly used for this purpose. Sentronic was worked with major system interface providers to ensure it is easy for customers to control and store data from our NIR PAT systems into such software packages. We have relationships with the following System Interfaces:

- synTQ from Optimal

- SIPAT from Siemens

- ProAxesS from KAX

- PharmaMV from Applied Materials

The available OPC interface as well as a comprehensive SDK are providing a high level of flexibility for integration into any specific data management or control system!

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.