Overview

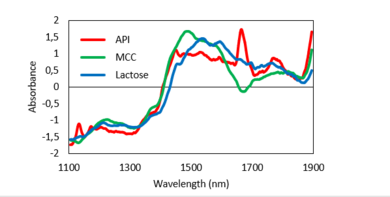

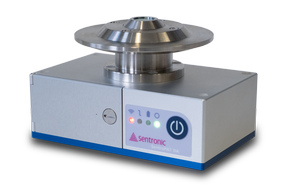

The SentroPAT BU II offers highest performance and reliability for NIR based PAT system to monitor blend uniformity during bin blending. With many dedicated features such as battery operation, position sensor and WiFi communication it is a perfect fit to the needs of this application.

- Highest spectra performance and long term stability

- Functionality fully dedicated for use in moving conditions

- Variety of software features for BU monitoring combined with multiple interfaces to third party software packages

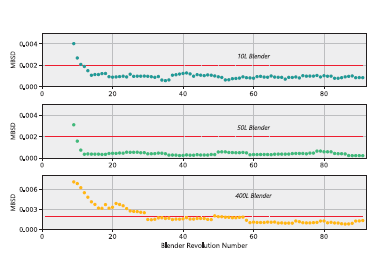

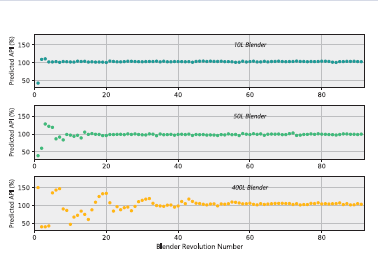

Applications

Explore the possibilities the SentroPAT BU II offers for the monitoring of the quality of your blend.

Technical Data

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

FAQ

Find answers to common questions about the SentroPAT BU II, including installation, positioning, and system integration. If you need further details, feel free to contact our team.

The SentroPAT BU II is equipped with a MEMS-based position sensor that triggers measurements when material covers the measurement window, which is installed in the IBC or its lid. The measurement position can be influenced by factors such as the fill level, rotation characteristics, and rotation speed. However, in most cases, the default settings provide reliable operation. For specific scenarios, the system settings can be easily adjusted within the software.

The SentroPAT BU II is mounted using a sanitary 4" clamp attached to a flange with a sapphire window. These flanges are designed to be welded into the IBC or its lid and are available as standard accessories. If needed, our engineering team can explore customized adaptations, such as different diameters, adapters for existing ports, or other installation-specific requirements.

Related Products

Explore alternative and complementary NIR PAT solutions for bin blending processes.