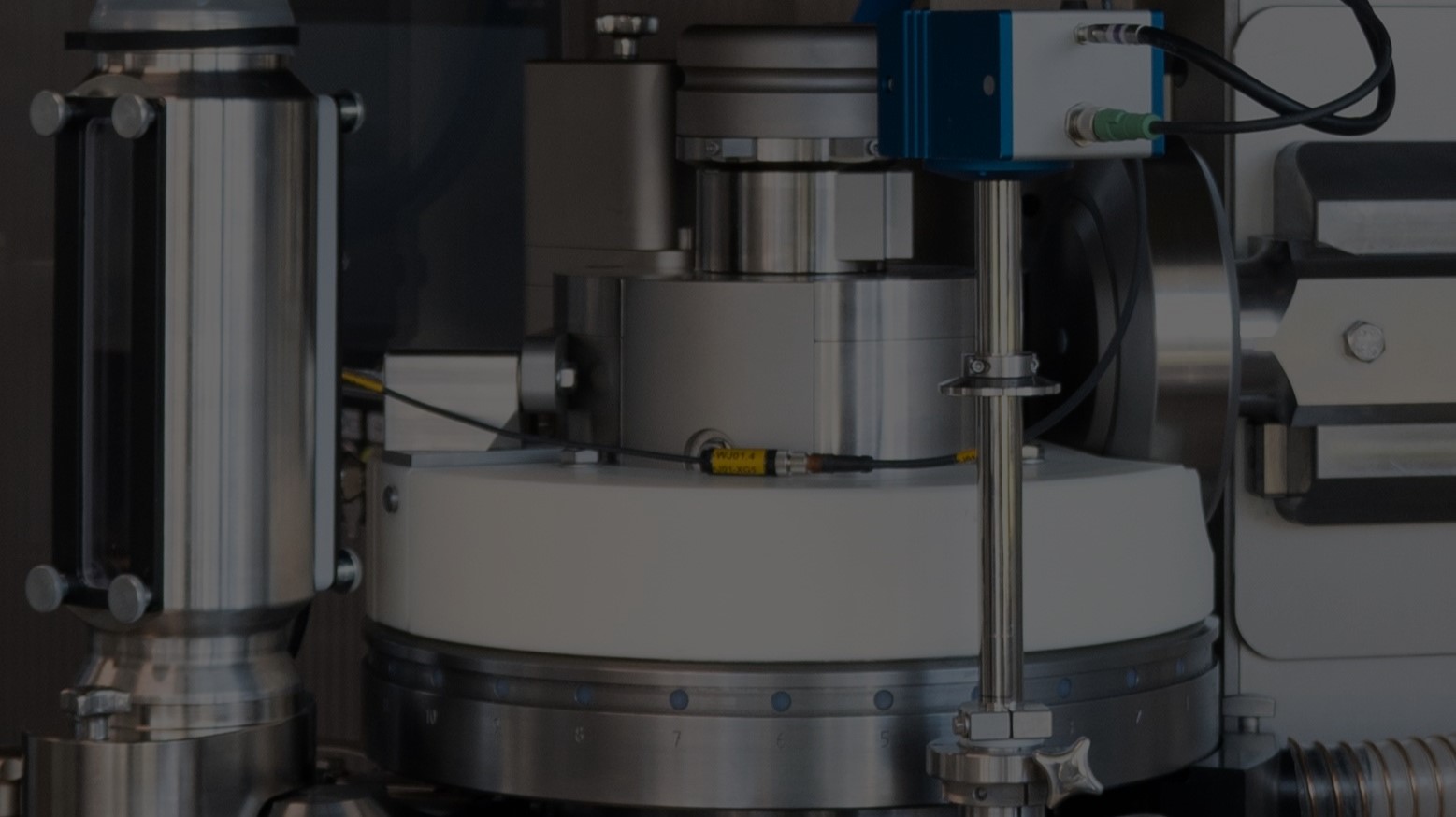

NIR in the tablet press feed frame

Gain instant insights into critical quality attributes during tablet production, enhancing process control, reducing waste, and ensuring compliance—in real time.

Unlock the Final Quality Checkpoint Before Tablet Compression

At the final checkpoint before tablet compression, the feed frame offers a unique opportunity to monitor critical quality attributes. A fast inline NIR PAT sensor at this stage provides valuable insights into blend potency and uniformity just before tablets take shape. However, this challenging environment demands systems that are both robust and long-term stable.

What Can Be Measured in the Feed Frame?

A fast inline NIR PAT sensor in the feed frame delivers precise measurements of critical quality attributes, including:

- Blend Potency: Ensure the correct active ingredient concentration throughout the batch. Detect segregation

- Blend Uniformity: Verify consistent distribution of components to avoid dosage variability.

- Content Uniformity (CU) Input: Provide reliable data for CU calculations, supporting compliance with regulatory standards and Realtime release testing.

Built on Experience

- We have been involved in PAT for the tablet press for a long time. A talk by the RCPE at our PAT meeting 2013 was demonstrating the use of the NIR inline measurement with the SentroPAT FO to monitor API concentration over batch production and showed, how efficiently segregation can be detected.

- In 2017 a team of pfizer PAT scientists worked with us on the improvement of system matching capabilites as part of the Pfizer PCMM development, which is one of the first real implementations of continuous manufacturing in pharmaceutical OSD production.