Overview

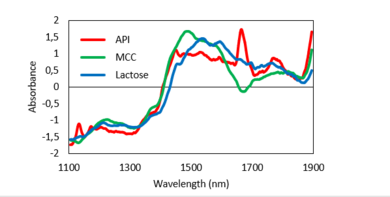

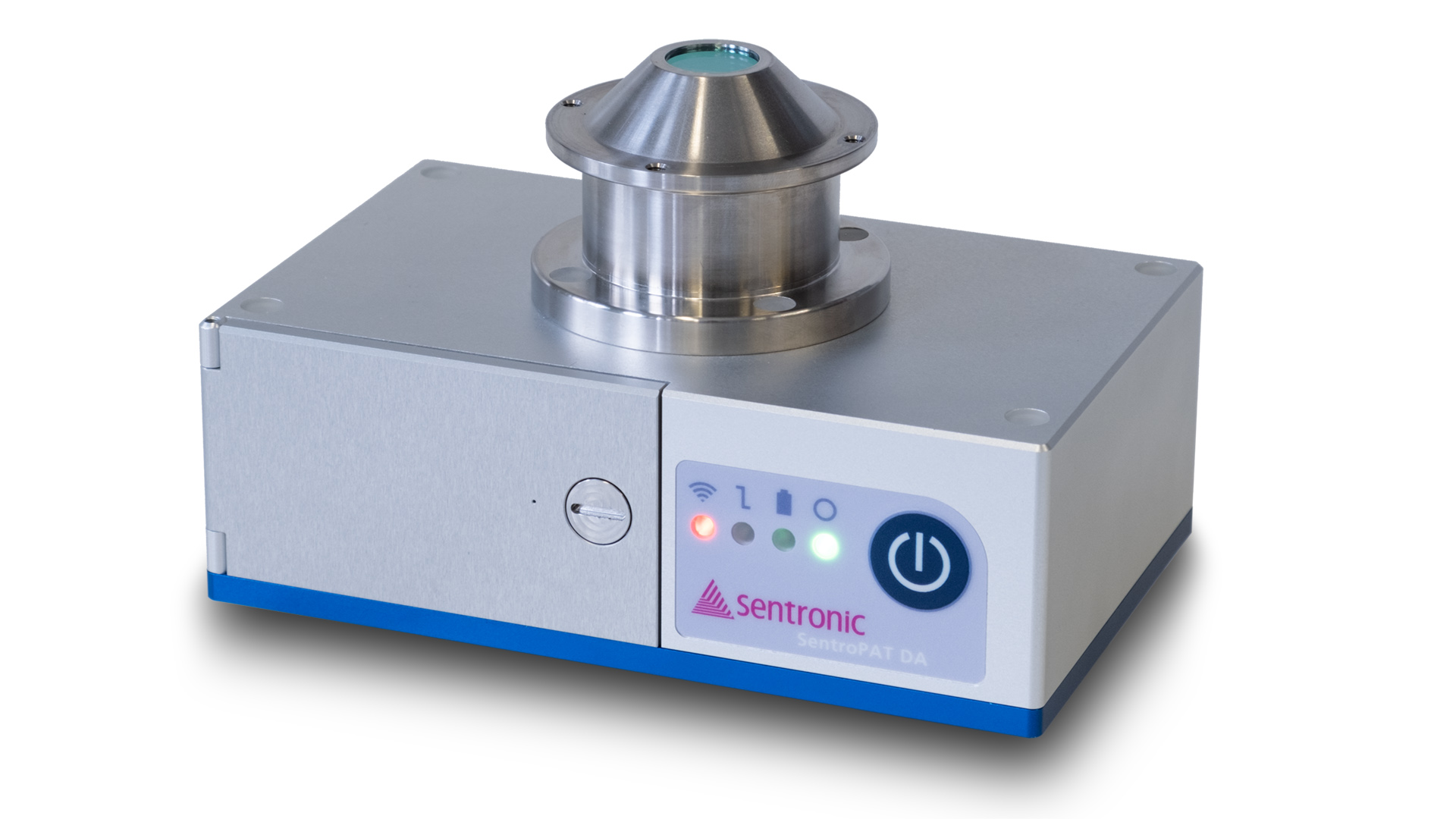

The SentroPAT DA is a compact NIR analyzer for non-invasive, online monitoring of pharmaceutical powder bin blending. It provides valuable insights and controls blend time, optimizing production efficiency. Compatible with various blenders, this system features a high-performance InGaAs diode array spectrometer for accurate spectral resolution, long-term stability, and superior system-to-system comparability.

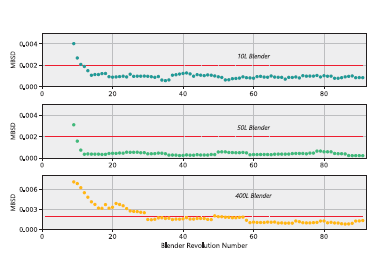

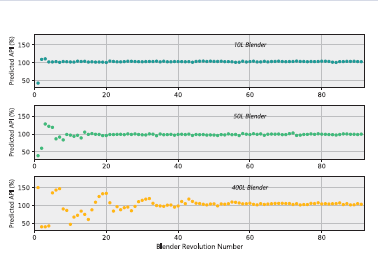

The system allows real-time monitoring of blend uniformity and quantitative analysis of APIs using chemometric models, eliminating the need for traditional lab sampling. Its user-friendly design includes simple mounting, minimal maintenance, and easy cleaning for GMP compliance.

Data integrity is maintained through embedded buffering and seamless integration with plant IT systems, ensuring secure, real-time data transmission. The SentroPAT DA enhances blending control, reduces costs, and supports consistent product quality.

Applications

Explore the possibilities the SentroPAT DA offers for the monitoring and end point detection of your bin blending process.

- High-performance InGaAs diode array spectrometer

- Extended spectral range for full CH-region covering

- Compact and lightweight design

- Non-invasive, contactless measurement

- WiFi transmission

- Seamless integration into PAT management systems

- User-friendly mounting and GMP-compliant surfaces

- Built-in accelerometer for measurement triggering

- No need for lamp replacement

- Compliance with USP<1856> and EP 2.2.40 standards

Technical Data

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

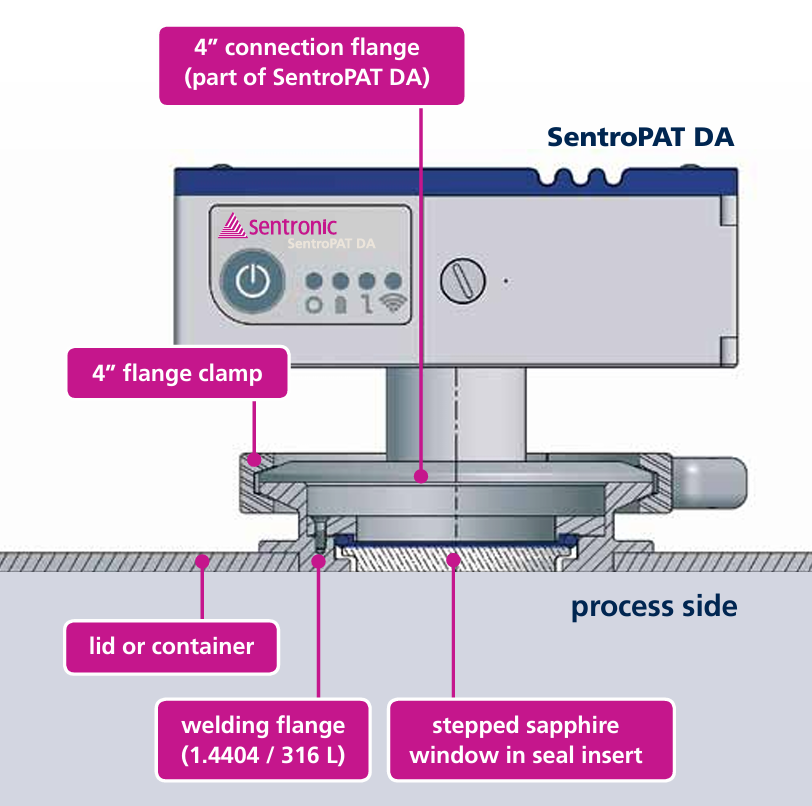

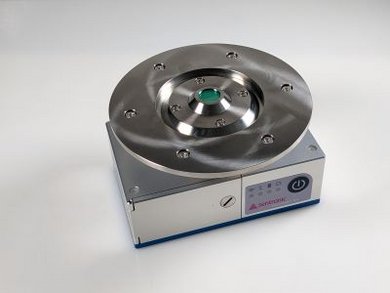

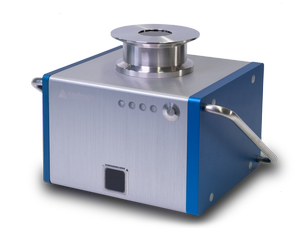

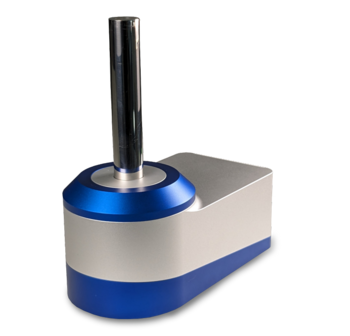

Mounting options

Several mounting options are available to enable the use of the system with different scale and types of blenders. Contact us, if you need help with you specific integration requirements!

Frequent Asked Questions

Find answers to common questions about the SentroPAT DA and its applications in pharmaceutical manufacturing.

The SentroPAT DA stores the 600 most recently collected spectra in a buffer, which will be sent to the External PC once Wi-Fi communication is established. It is very rare that a single blend lasts 600 revolutions or more, so the liklihood of losing data during blending due to loss of Wi-Fi is very, very low.

No, the sources are intended to last the lifetime of the instrument. A second, redundant source has been added to the system and can be switched to via a software parameter change if an NIR source stops functioning, avoiding unnecessary service downtime.

It's hard to give a definite answer here without knowing specifics of the blender, it's associated enclosure, and how the SentroPAT DA will be mounted to the blender. Many customers have successfully integrated a SentroPAT DA on their small scale blenders, including V-blenders. If you have questions about your system, please reach out!

There are two ways to power the system. When connected to a power supply, the system automatically recharges its internal Li-Ion battery. Additionally, the battery can be easily swapped for a fully charged one. An external charger, which is included, allows charging additional batteries while the system remains in use. This is particularly useful for long operating periods without sufficient downtime for recharging.

In some cases, customers ensure continuous power supply by using slip rings on the blender.

Additional Products

Explore our wide range of innovative products designed to meet the diverse needs of pharmaceutical manufacturing.