Overview

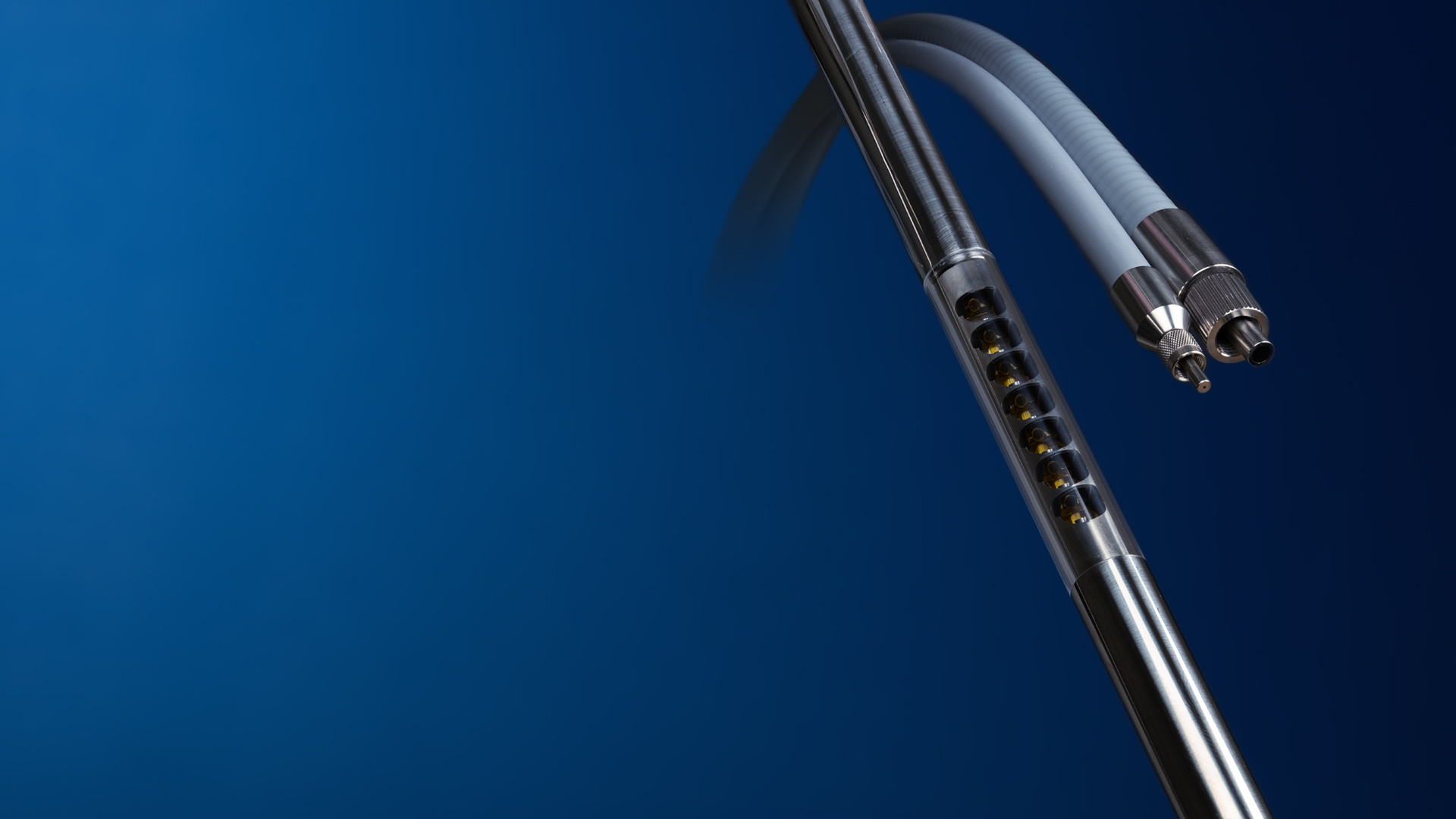

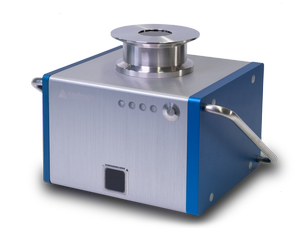

The SentroProbe MS7 is a multispot process probe designed to take measurements across a chute filled with moving powder in diffuse reflectance mode.

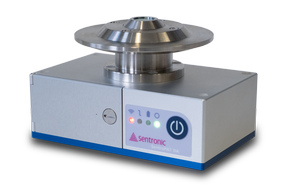

It is commonly paired with the GEA Consigma Light House assembly and used to analyze powder in the slow-moving zones between the outlet of the final blender in a GEA CDC line and the tablet press. When combined with a SentroPAT FO with an internal 9W NIR source, the SentroProbe MS7 can provide vital process information about a continuous manufacturing process.

- Seven measurements spots assess large masses of across a moving powder stream

- Drift correction of NIR source in connected SentroPAT FO provides outstanding long term stability

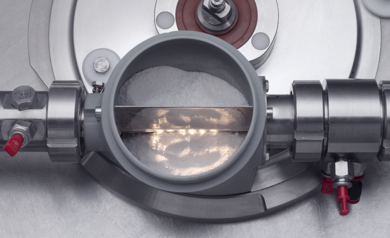

- Combatible with GEA Consigma Light House assembly, including wash-in-place (WIP) skid, providing in-line probe cleaning and referencing capability

- GMP-friendly design

Applications

Combined with a SentroPAT FO system, the SentroProbe MS7 is a powerful tool for monitoring several different types of oral solid dose unit operations. The ability to clean the probe in place when combined with the GEA Consigma light house assembly makes the SentroProbe MS7 an attractive option for dry blends that have a tendency to stick to probe surfaces.

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

Frequent Asked Questions

Learn more about the SentroProbe DR MS7 NIR and its wide range of applications in pharmaceutical manufacturing. This section provides additional insights and detailed information to help you fully understand the potential and versatility of our cutting-edge sensor technology.

The maximum stock is 5.5m.

It depends! Both probes can be used to assess critical quality attributes of blends during processing, but differ in how their interface to a process. The different probes would also require different process simulators if a process simulator is desired for method development. It is hard to give a detailed analysis without more information, but in general: both probes can be used successfully for many applications, with the limiting factor often being how the probe is integrated into the process. For example, it would be very hard to put a SentroProbe DR MS7 into a tablet press or a SentroProbe DR LS into a GEA LightHouse Probe assembly.

We have many installations in GMP commercial manufacturing that use a SentroProbe MS7 in product contact. Suffice to say, yes, this has been accepted by regulators. To that end, we provide material certificates with each SentroProbe MS7.

We generally recommend 70% isopropanol. However, if you’d prefer to use a different cleaning solution, please contact your local Sentronic representative to discuss compatibility with our probes.

Additional Products

Explore our wide range of innovative products designed to meet the diverse needs of pharmaceutical manufacturing.