Overview

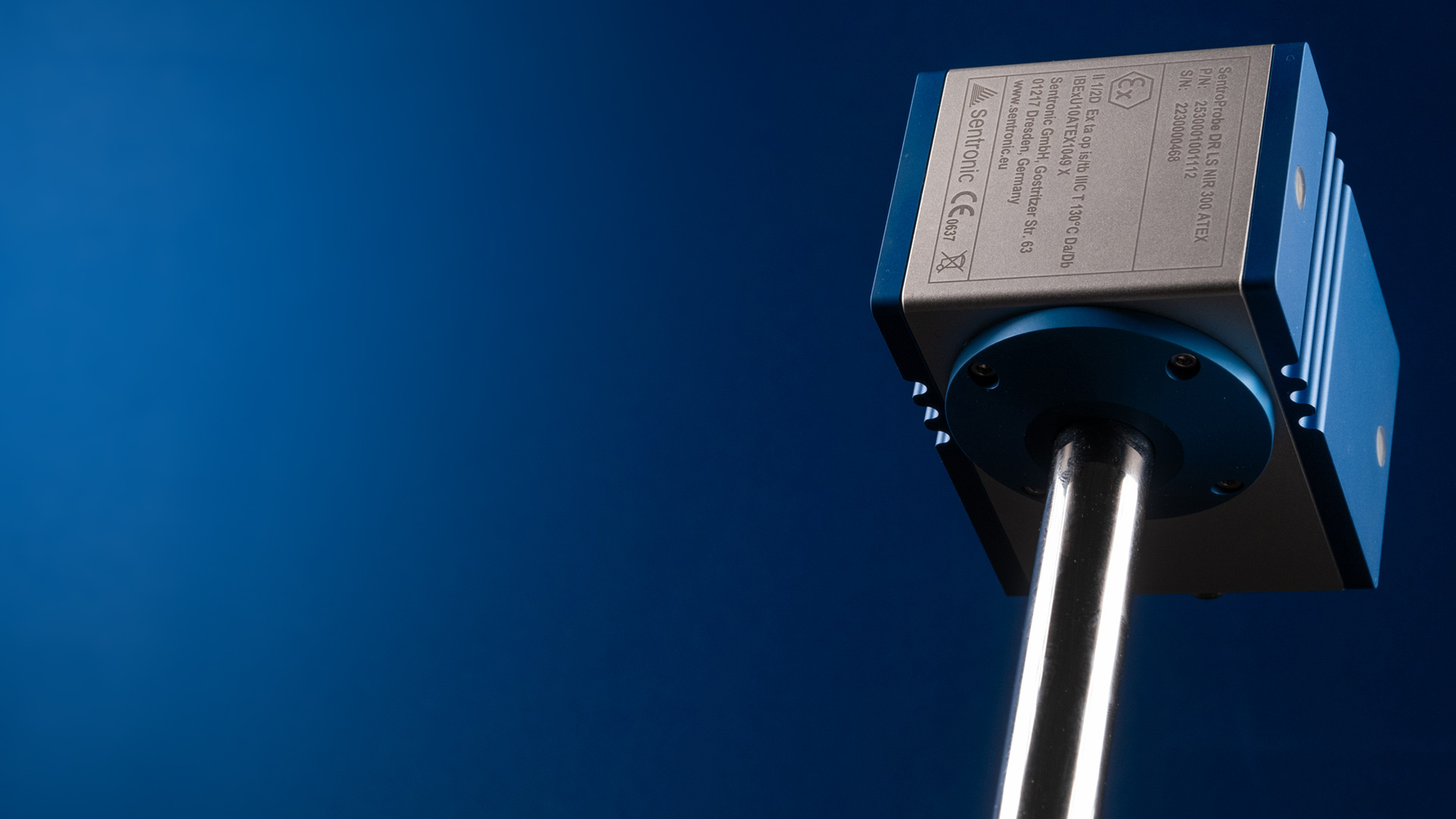

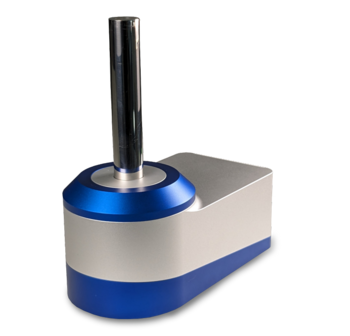

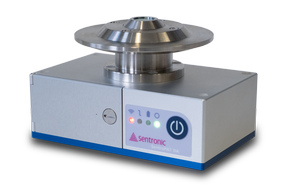

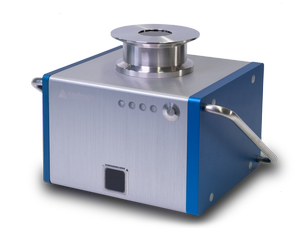

The SentroProbe DR LS is an ATEX certified probe for measurements in diffuse reflectance. It is a perfect fit to the SentroPAT FO systems and offers several feature for reliable PAT measturements in various unit operations within solid dose pharmaceutical manufacturing processes.

- Two internal light sources

- Internal reference for drift correction and outstanding long term stability

- Probe tip with ¾" and different lengths

- GMP friendly design

- ATEX zone 20/21 certified

Applications

Combined with a SentroPAT FO system the SentroProbe DR LS is a powerful option to monitor many different unit operations in pharmaceutical industry but also in many applications where solids have to be measured in diffuse refelectance.

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

Frequent Asked Questions

Learn more about the SentroProbe DR LS and its wide range of applications in pharmaceutical manufacturing. This section provides additional insights and detailed information to help you fully understand the potential and versatility of our cutting-edge sensor technology.

For SentroProbe DR LS probes, not very much! This is partially because of the tight manufacturing controls in place. It is also because the SentroProbe DR LS is intended for direct product contact use and does not use focusing optics. As a result, small differences in manufacturing tolerances are less impactful to measurement spot size, alignment, etc as they might be with a focused spot.

Lastly, for many applications, common spectral preprocessing methods minimize the impact of small changes in signal intensity from probe-to-probe. As a result, for many applications, changing a probe can be done without updating a chemometric model. However, the impact of changing a probe should still be assessed.

Yes. It should be noted that the thickness of the process windows should be kept to a minimum as the thicker the window is, the more attenuated the NIR signal will be. However, Sentronic has many customers using SentroProbe DR LS systems with a process window.

We recommend changing the NIR sources out after a year and executing performance verification testing. However, if a user is in a development lab, using the system infrequently, or in an industry with less stringent regulation than the pharmaceutical industry, we recommend changing lamps when their intensity starts significantly decreasing. The Lamp Check validation test in SentroSuite can help users assess when that happens.

Additional Products

Explore our wide range of innovative products designed to meet the diverse needs of pharmaceutical manufacturing.