Overview

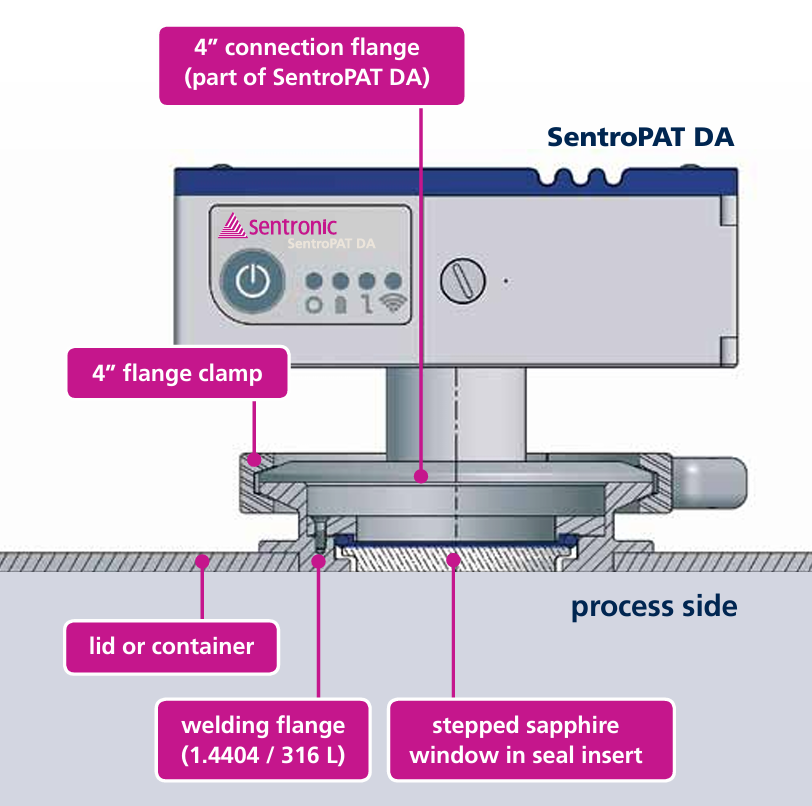

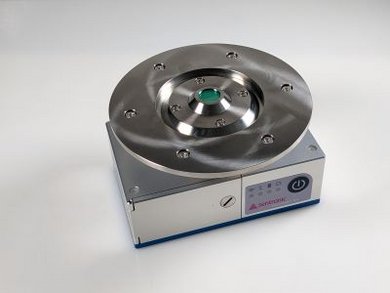

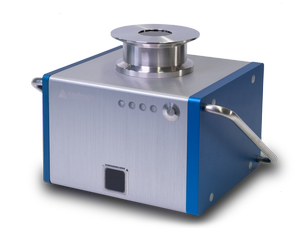

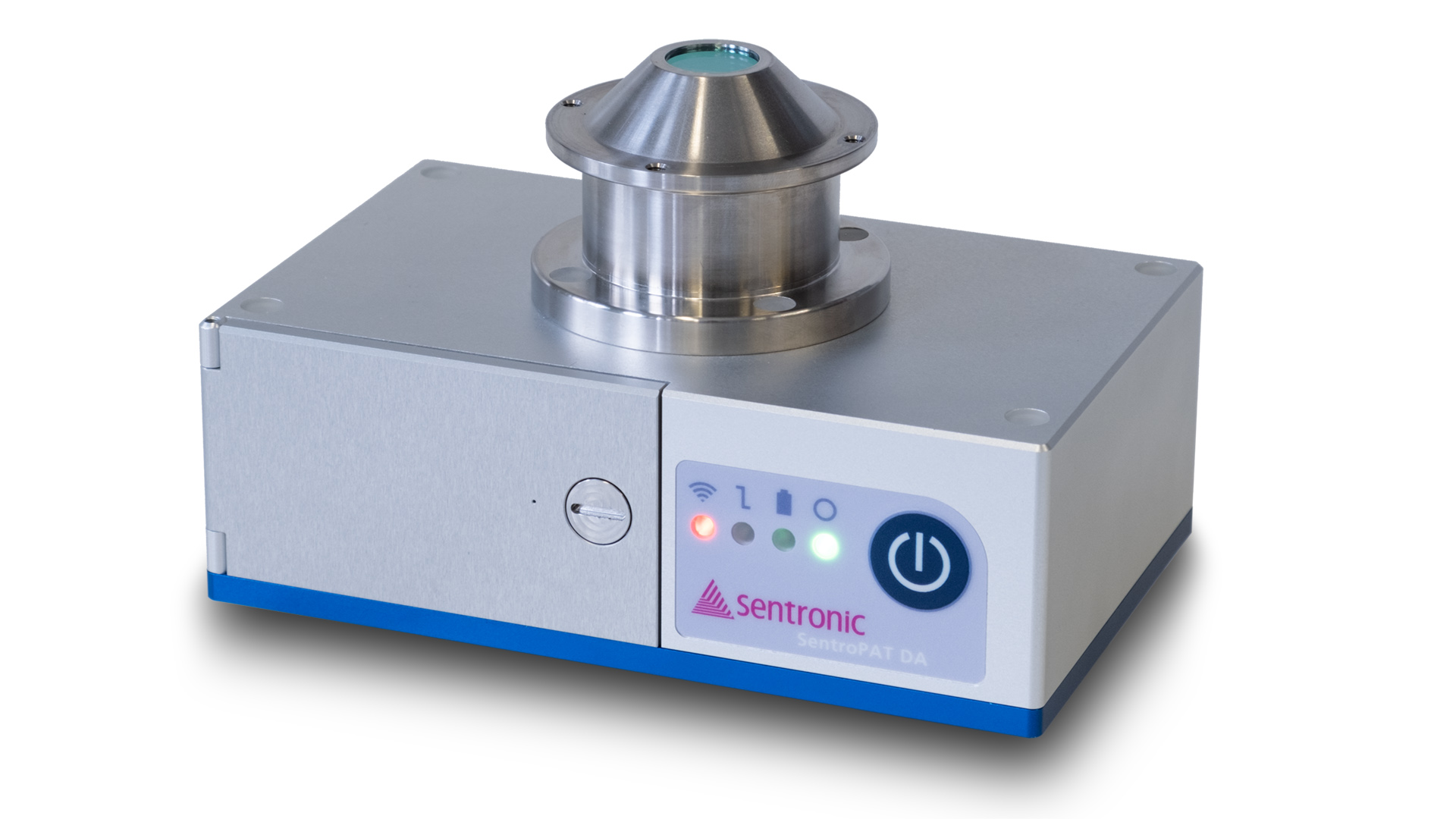

The SentroPAT DA is a compact NIR analyzer for online monitoring of powder bin blending. It provides valuable process insights and can be used to determine blend end-point in real time, optimizing production efficiency. The system is compatible with many suppliers’ blenders and with most blender sizes.

The SentroPAT DA includes an internal battery, providing at least 6 hours of continuous operation on a blender, as well as internal wi-fi connections. This enables fully wireless connection on a blender. An internal gyroscope allows the system to only collect data when powder is likely to be in front of the process window the system mounts on to, which is typically added to a modified blender bin lid.

The SentroPAT DA includes a high-performance diode array spectrometer, covering the majority of the NIR spectral region. The system’s spectral resolution, long-term stability, and superior system-to-system comparability make it a reliable and robust NIR PAT solution for development and manufacturing. Data integrity is maintained through embedded buffering and seamless integration with plant IT systems, ensuring secure, real-time data transmission.

Applications

The SentroPAT DA provides key process insights into your bin blending process:

- Compact and lightweight design, fits on most blenders

- Wide spectral range to ensure sensitivity to most APIs, excipients, and lubricants

- High resolution and low noise ensure the system is appropriate for use, even for low dose formulations

- Measurement without product contact

- Completely wireless operation on a bin blender

- Seamless integration into PAT management systems

- User-friendly mounting on a bin

- Built-in accelerometer to ensure easy and high-quality spectral data collection

- No wear parts or spare parts to manage

- Compliant with USP<1856> and EP 2.2.40 standards

- Software compliant with 21.CFR.Part 11

Technical Data

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

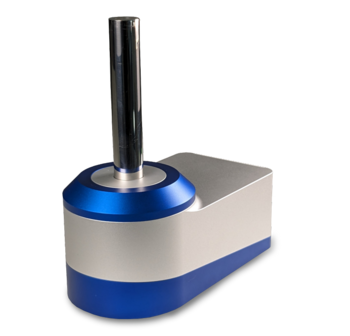

Mounting options

Several mounting options are available to enable the use of the system with different scale and types of blenders. Contact us, if you need help with you specific integration requirements!

Frequent Asked Questions

Find answers to common questions about the SentroPAT DA and its applications in pharmaceutical manufacturing.

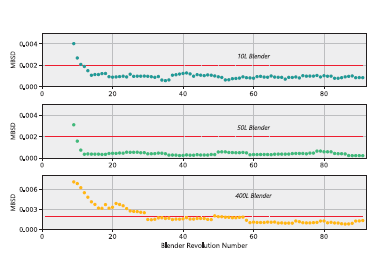

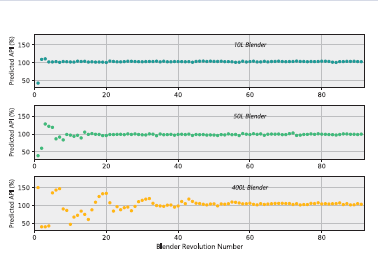

Near infrared (NIR) spectroscopy is sensitive to most excipients and active pharmaceutical ingredients (APIs) and can tell when the relative amounts of the excipients/APIs in its measurement window are changing. We can take advantage of this sensitivity and build very simple models that can tell when the NIR spectra stop changing. Once that happens, it's very likely that blend uniformity has been achieved (although this of course should be validated before being used in manufacturing).

One complication with bin blending is that blend isn't always in front of the NIR's measurement window. For example, there are periods during a rotation when the NIR's measurement window has no powder in front of it, such as when measurement window is at its highest point in rotation and gravity pulls powder away from the window. NIR PAT must then find a way to either filter out measurements made when there's no material in front of the window or trigger measurements only when powder is in front of the window. Sentronic users the latter approach and uses an internal angle sensor to trigger measurements only when a bin's position during a rotation will result in powder being in front of the window.

One. Users can start a continuous measurement and get spectra all throughout a bin's rotation. However, they'll have to filter out data collected when no material is in the NIR measurement zone. Some users do this to map out the angles of the bin, relative to the floor, where powder is in front of the window. This helps them robustly set a measurement trigger angle and can provide some information on blending dynamics.

The SentroPAT DA stores the 600 most recently collected spectra in a buffer, which will be sent to the External PC once Wi-Fi communication is established. It is very rare that a single blend lasts 600 revolutions or more, so the liklihood of losing data during blending due to loss of Wi-Fi is very, very low.

No, the sources are intended to last the lifetime of the instrument. A second, redundant source has been added to the system and can be switched to via a software parameter change if an NIR source stops functioning, avoiding unnecessary service downtime.

It's hard to give a definite answer here without knowing specifics of the blender, it's associated enclosure, and how the SentroPAT DA will be mounted to the blender. Many customers have successfully integrated a SentroPAT DA on their small scale blenders, including V-blenders. If you have questions about your system, please reach out!

There are two ways to power the system. When connected to a power supply, the system automatically recharges its internal Li-Ion battery. Additionally, the battery can be easily swapped for a fully charged one. An external charger, which is included, allows charging additional batteries while the system remains in use. This is particularly useful for long operating periods without sufficient downtime for recharging.

In some cases, customers ensure continuous power supply by using slip rings on the blender.

The SentroPAT BU II has a wavelength range of 1350 - 1800 nm with a resolution of NMT 2 nm FWHM. The SentroPAT DA has a wavelength range of 1100 - 1900 nm with a resolution of NMT 10 nm FWHM. The wavelength and resolution are the most obvious differences between the two systems, in addition to some differences in signal-to-noise owing to the difference in spectrometer design (SentroPAT BU II: MEMs-based spectrometer; SentroPAT DA: diode array spectrometer).

Both the SentroPAT BU II and SentroPAT DA are capable instruments. The SentroPAT DA is much easier to fit on small bins owing to its smaller size and lower weight. However, for the most challenging applications and for applications that do not need to monitor bands below 1350 nm or above 1800 nm, it may be advisable to look at a SentroPAT BU II due to its high signal-to-noise and outstanding spectral resolution. However, most NIR PAT bin blending applications in OSD pharmaceutical manufacturing can be well served by a SentroPAT DA.

Additional Products

Explore our wide range of innovative products designed to meet the diverse needs of pharmaceutical manufacturing.