Real-Time Monitoring of Continuous Processes using NIR based PAT

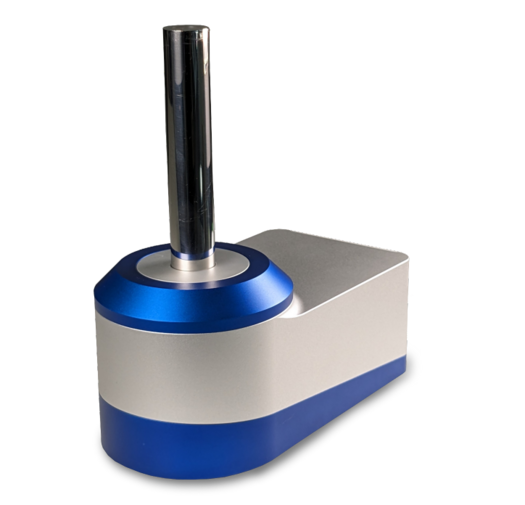

Get continuous insights into your continuous manufacturing process with a SentroPAT NIR system.

Make Sure Every Unit Dose is On Target

Continuous blending and granulations are critical unit operations in continuous manufacturing. NIR PAT probes monitoring the outlet of a granulator or continuous blender can help detect segregation of blend when it happens, enable material segregation so every unit dose is within process control limits, and ensure blend potency is on target.

Where Can I Install my NIR Probe?

A NIR probe can mounted in several locations in a continuous manufacturing rig:

- Outlet of a Wet Granulation Unit Operation: Ensure that granules are formed correctly and that moisture is within specification prior to extragranular blending.

- Outlet of a Dry Granulation Unit Operation: Ensure that granules are formed correctly and that there is no evidence of blend segregation prior to extragranular blending.

- Outlet of the Extragranular Blending Unit Operation: Provide reliable data for BU, CU, and blend potency in final blend immediately prior to tableting.

Built on Experience

We have been involved in PAT for the tablet press for a long time. A talk by the RCPE at our PAT meeting 2013 was demonstrating the use of the NIR inline measurement with the SentroPAT FO to monitor API concentration over batch production and showed, how efficiently segregation can be detected.

- Scientists at several major pharmaceutical companies have successfully used our SentroPAT NIR probes in approved continuous manufacturing filings.